When Did You Last Check Your Forklift Forks?

Forklift forks are critical components in material handling operations. Regular inspections are essential to ensure safety, comply with regulations, and maintain operational efficiency.

Importance of Fork Inspections

Over time, forklift forks can experience wear and tear, leading to potential safety hazards. Regular inspections help identify issues early, preventing accidents and costly downtime.

Inspection Frequency

- Daily Checks: Operators should perform visual inspections at the start of each shift to identify any obvious damage or wear.

- Thorough Examinations: As per the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER), forklifts must undergo a thorough examination at least once every 12 months, or more frequently depending on usage and risk assessment.

Common Signs of Fork Wear

- Surface Cracks: Inspect for any visible cracks, especially around the heel and weld areas.

- Blade and Shank Wear: Measure the thickness; if it's reduced by 10% or more from the original, the fork should be replaced.

- Tip Alignment: The difference in height between fork tips should not exceed 3% of the blade length.

- Angle Deviation: The angle between the blade and shank should remain within 3 degrees of the original specification.

- Positioning Lock Integrity: Ensure that the positioning locks are present and functioning correctly.

Safety and Compliance

Adhering to inspection schedules and promptly addressing any identified issues ensures compliance with safety regulations and protects both personnel and equipment.

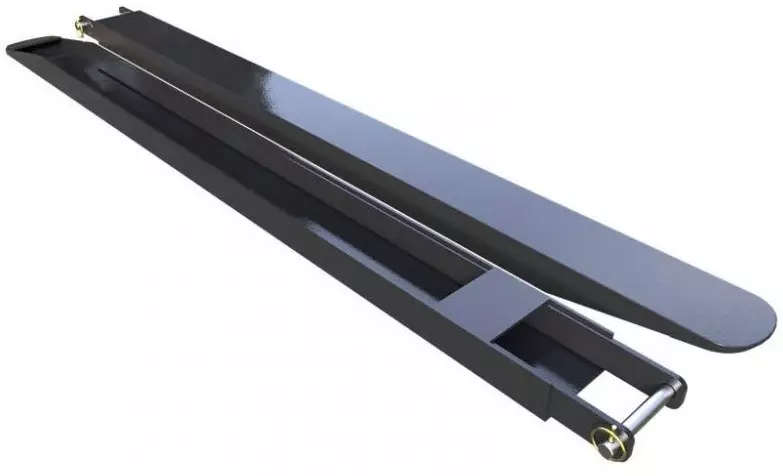

Explore Our Forklift Forks

At Liftruck UK, we offer a wide range of forklift forks to suit various applications:

- Standard Forklift Forks – Durable and reliable forks for everyday use.

- Fork Extensions – Extend your existing forks to handle longer loads safely.

Contact Us

For expert advice on forklift fork inspections or to find the right forks for your equipment, please contact our team:

- Email: info@liftruck.co.uk

- Phone: 0800 458 8025